EnvisionTEC

Westwind and EnvisionTEC

Westwind is proud to partner with EnvisionTEC, innovators in 3D technology, whose printers are known for delivering excellent precision, smooth surface finish down to 10 microns, functionality and speed. And with 190 materials available, you can print just about any application.

Featured Partner Products

Continuous (CDLM) DLP Printers

EnvisionTEC launched their Continuous Digital Light Manufacturing technology in early 2016 with the Micro Plus cDLM. The process allows for continuous motion of the build plate to deliver exceptional build speeds. They’ve continued to innovate and expand this family of printers, increasing the build envelope, improving resolution, including heating elements. These printers are FAST.

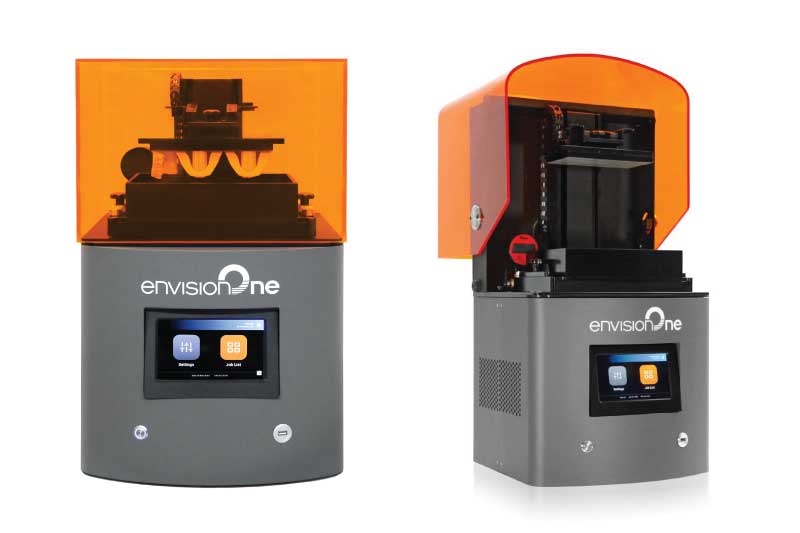

Desktop DLP Printers

EnvisionTEC’s professional-grade desktop 3D printer family uses advanced DLP technology. Offering fast and accurate 3D builds with sizes up to 71.7 cubic inches and accuracy levels down to 30 microns, these machines are easy to use, with few moving parts and minimal consumable components. Switching between materials is quick and easy, with little to no waste. Used by thousands of professionals worldwide, including manufacturers of jewelry, hearing aids, dental models and appliances, medical devices, consumer goods, mechanical prototypes and more.

Perfactory DLP Printers

Designed for real production and build sizes up to 253.6 cubic inches, this “personal factory” line of 3D printers uses exclusive DLP technology and offers the ability to fully automate production. From aerospace to entertainment to medical, these printers deliver regardless of geometric complexity.

3SP Printers

EnvisionTEC’s 3SP technology uses a UV laser to rapidly scan, spin and selectively photocure a variety of resins into large, durable parts up to 5800 cubic inches. A true industrial 3D printer, it’s at home on a factory floor or in a machine shop, hospital, or lab. These printers can build a range of manufacturing objects, from functional gears, valves and pumps to fasteners, jigs, fixtures or end effectors. You can also use it for mass customized production in the dental industry. No sacrificing accuracy or surface finish with 3SP technology (which isn’t the same as SLA). Oh, it can also 3D print tooling for thermoplastic injection molding.